Supply Chain Management

Bridge the Gap Between Engineering and Procurement

BOM Management Integrated into Hardware Development

Procurement and purchasing teams can actively participate in the design decisions throughout the entire development lifecycle. If you need to replace a part at any stage, you have the tools to trace the part and estimate the impact with the where-used functionality and a straightforward process to manage the change: submit an engineering change order (ECO) directly from the BOM document or attach a comment to the BOM entry.

Proactive Risk and Cost Management

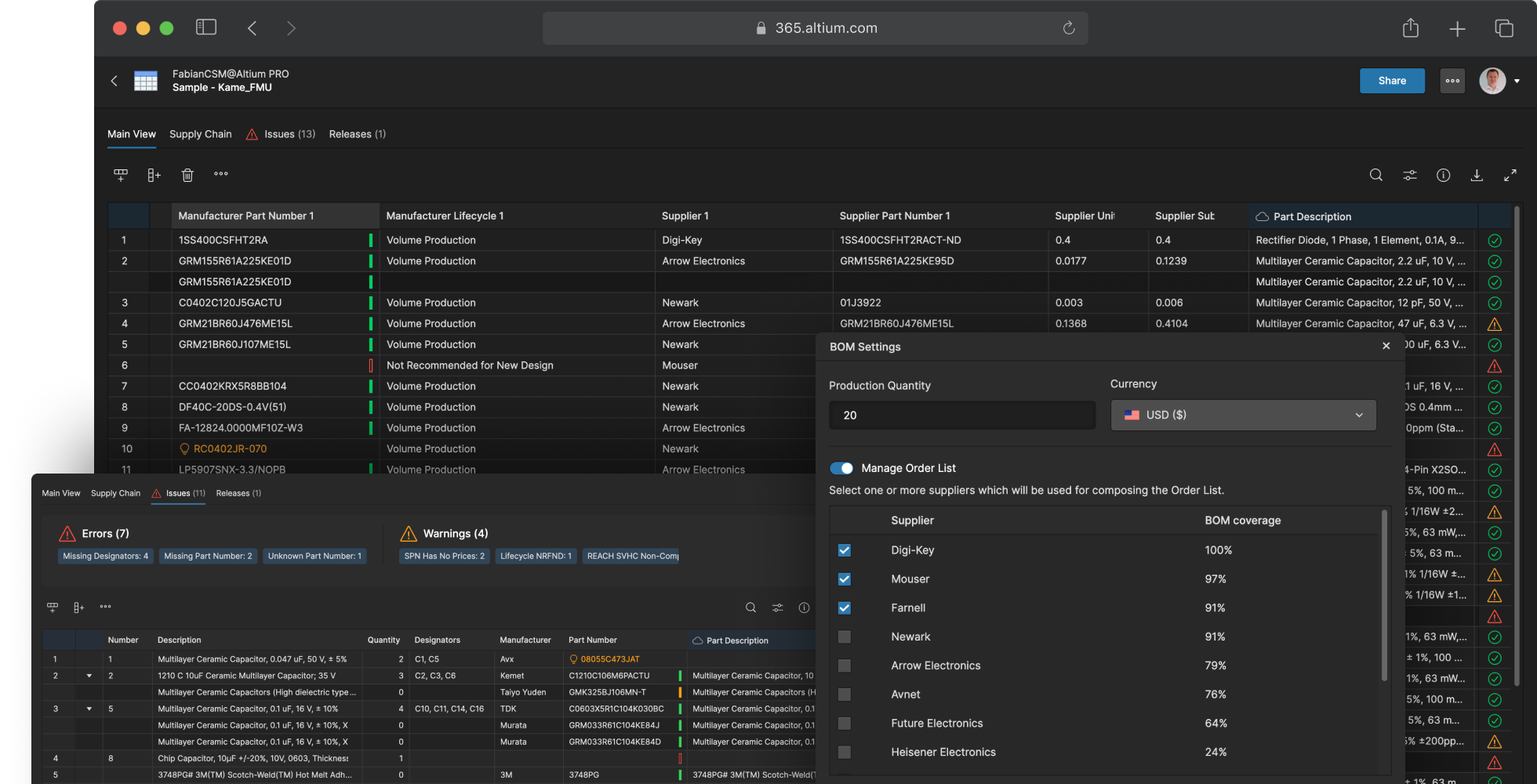

The BOM document is automatically enriched with up-to-date price and availability data, manufacturer life cycle information, and alternative part choices. Altium 365 integrates with the leading parts data providers: Octopart, SiliconExpert, and S&P Global (formerly IHS Markit). You can proactively monitor BOM statuses and set up BOM checks to monitor issues.

Decision-Making with up-to-date Supply Chain Data

Embed up-to-date supply chain data within your design flow. Enable engineers and procurement teams to make informed decisions during part research with details on availability, compliance information, risks, and costs. Minimize back-and-forth discussions between teams and ensure alignment from the beginning. Experience improved communication, reduced time-to-market, and a cost-effective design lifecycle.

Key Applications

BOM Portal℠

Reduce design respins and accelerate time to market with Altium 365 BOM Portal. Gain valuable part data insights and collaboration features to make better-informed decisions throughout the product lifecycle. Leverage enriched part and supply chain data for informed BOM decisions, proactively mitigate supply chain risks, and simplify your BOM management with powerful functionality. Create and edit library components - or use the library from the designers team - for easy traceability and reusability. With the upcoming ECAD-Procurement CoDesign capabilities, you can ensure alignment, minimize iterations, and maintain digital continuity between teams.

.png)

SiliconExpert Integration

Upgrade your BOM management process with the SiliconExpert integration. Gain access to real-time, detailed component data directly from manufacturers. Drive your BOM strategy with the latest and most accurate information available. Get ahead with enhanced risk analysis, encompassing YTEOL (Years to End of Life) dates, multi-sourcing, and inventory risks, and effortlessly find superior alternate parts.

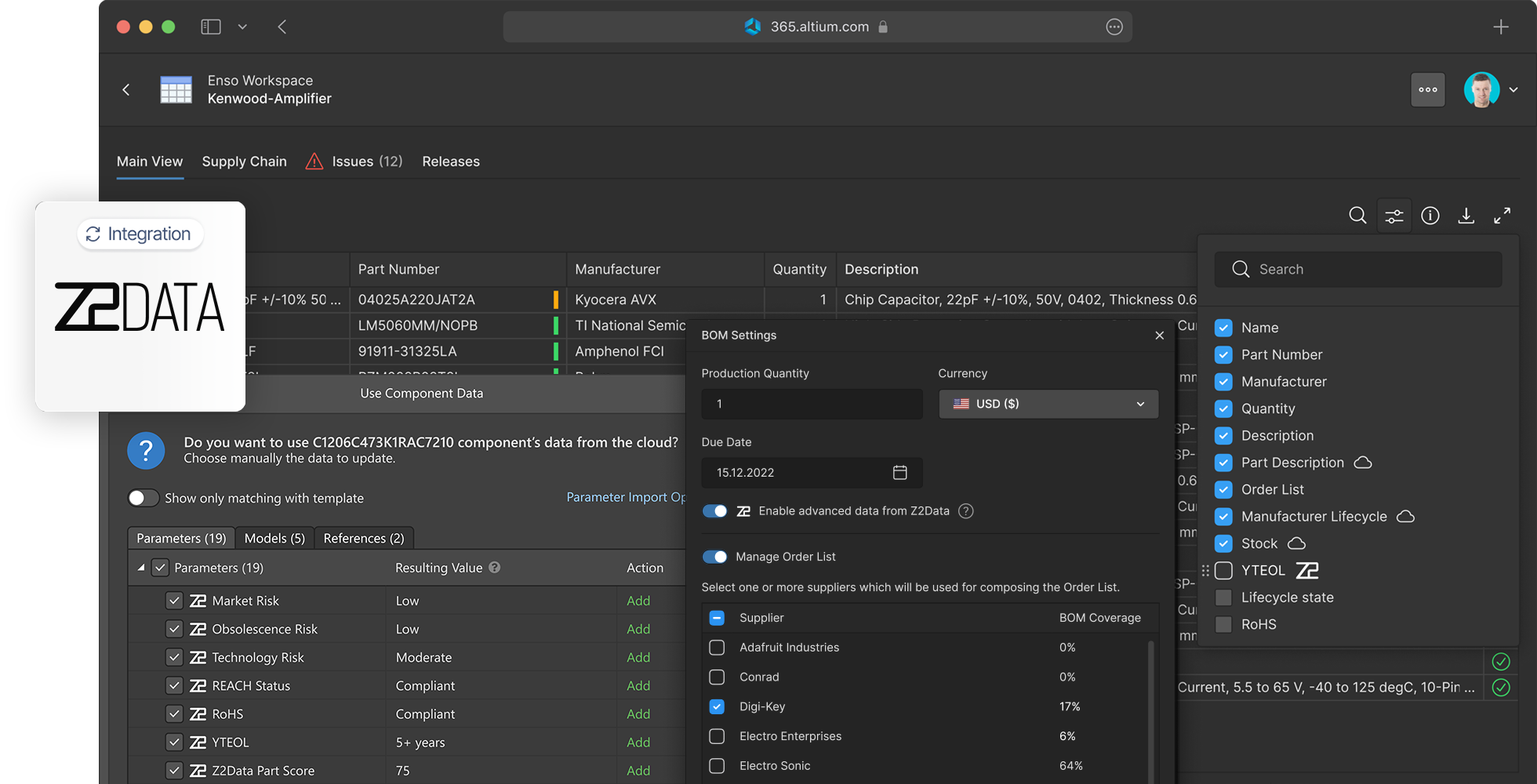

Z2Data Integration coming soon

Build resilience in engineering, compliance, and procurement powered by one of the most comprehensive supply chain and component data. Revolutionize how you manage your supply chain risk with integrated data, including detailed part datasheet, lifecycle data, RoHS & REACH status, and most importantly, Z2Data’s proprietary 6-point part scoring algorithm.

.png)

S&P Global (formerly IHS Markit) Integration

Improve your part selections with advanced component data from S&P Global (formerly IHS Markit) to make your Bill of Materials (BOMs) even more reliable. Replace Octopart parameters in the Manufacturer Part Search for the description, manufacturer lifecycle, technical parameters, and alternative suggestions. Additionally you will get datasheets from S&P Global as well as compliance information for RoHS and REACH SVHC.

.png)

Octopart Integration

Accelerate your design process with access to millions of ready-to-use components with rich parametric data in Altium 365 and Altium Designer. You’ll never have to worry about whether your components will be available for production with supply chain data available at your fingertips directly from the distributors. You can stay focused on the details of your design process without having to spend hours manually creating components.

Trusted by Industry

Leaders and Startups Alike

With over ten thousand companies worldwide using Altium 365 to design electronics,

the platform has become the new modern standard in hardware design.

“Usually, the first prototypes I do need to happen quickly. So we have 48h for boards, during which time I order components. Here is so much thanks to the ActiveBOM and the handling there, it simplifies the work immensely. Then I take these boards and send them to a local lab. They can hand/semi-automatically mount almost anything in 4-8 hours. ‘Yesterday’ this was done using paper and Excel. ‘Today’ we moved to Altium 365 with ActiveBOM. ‘Tomorrow’ I hope we could use the Assembly App where they can tick off anything they have mounted. It is just fabulous.”

“We now have the feature to check which component is in which product, and we can even see with ActiveBOM which components are end-of-life or obsolete. This is a great tool and gives a big, big benefit and also, it's possible for the purchasers that they check now inside Altium 365 which components are used where. And they can even check the availability and end-of-life information.”